Custom Fabricated Glued-Laminated Timber

Architectural-Grade Mass Timber Products From Tridome Structures

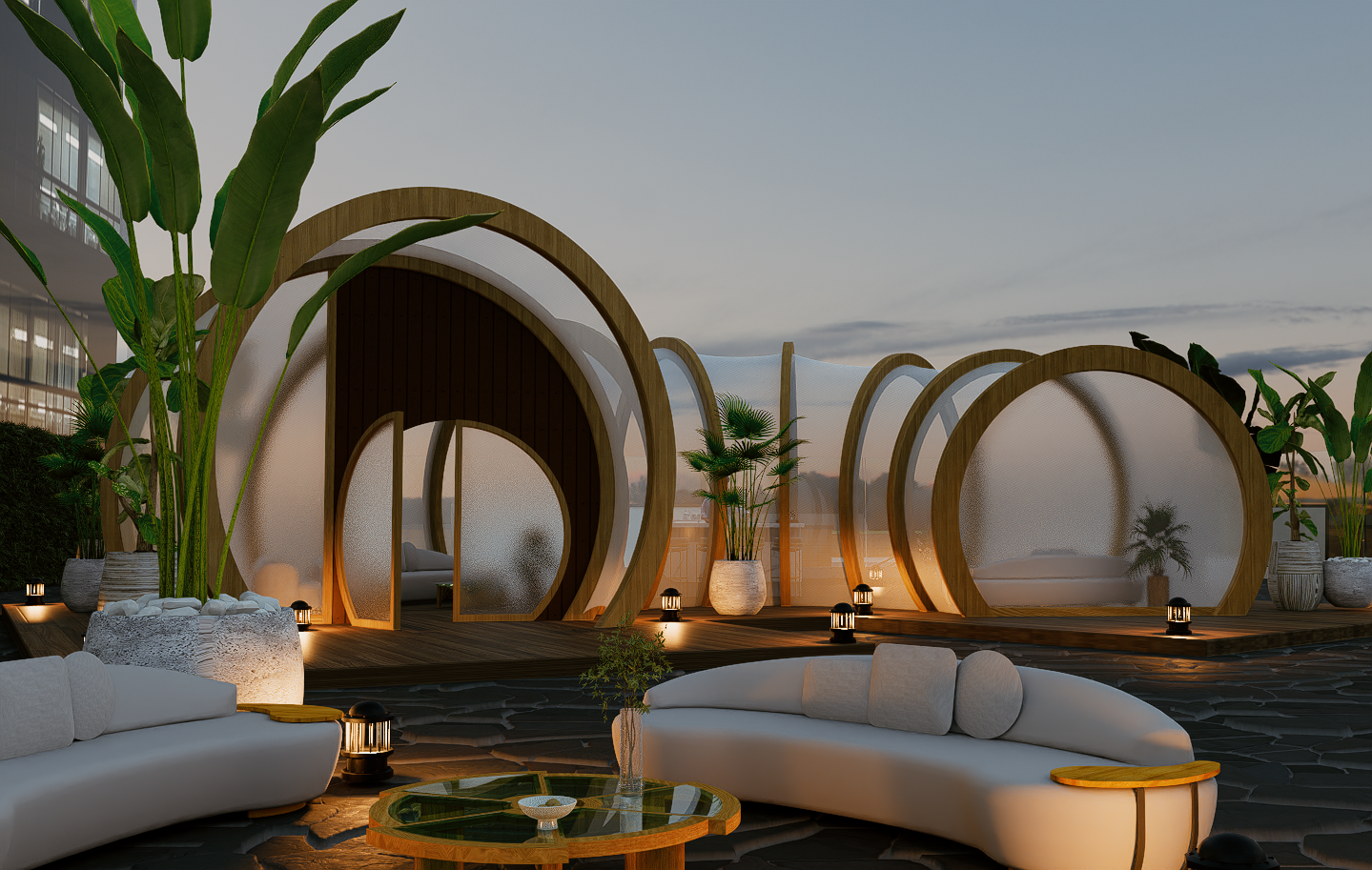

Tridome Structures is a glued-laminated timber (Glulam or GLT) producer based in the Northeastern United States. We specialize in custom fabricating architectural-grade glued-laminated timber panels, beams, and prefabricated components. Our innovative Glulam products combine the beauty of natural wood with the strength and stability of engineered wood products.

Glued-laminated timber, or glulam, is an engineered wood product made by joining several layers of lumber together with durable, moisture-resistant adhesives. The grain of the wood runs parallel to the length of the final product. This process creates a strong, stable, and versatile building material that is ideal for a variety of structural applications.

Glulam is a popular choice for structural components like beams, columns, and arches in both residential and commercial buildings. It is often used in situations where traditional lumber would be too weak or too short to span long distances. Glulam is also a good choice for projects where the appearance of the wood is important, as it can be finished to a high standard.

Our Glued-Laminated Timber Production Process

01 FSC-Certified Timber

Our production process begins with native Northeastern softwood lumber harvested from sustainably managed forests.

02 Inspection & Grading

Our strategic forest industry partners provide us with visually and mechanically graded raw materials specific to our needs.

03 Strength High-Grading

Once received, our team performs additional strength and aesthetic grading & sorting to produce special lam-stock.

04 Finger Jointing

The lumber is finger-jointed together to form planks of the desired length. This process creates a bond stronger than the wood around it.

05 Planing

The timber is planed to specification and to prepare the surface for adhesive coating.

06 Adhesive Application

Adhesives are applied to the faces through highly metered and controlled application methods in preparation for forming and pressing.

07 Lamination Pressing

Once adhesives are applied, the laminations are stacked in a custom press that forms them to the desired shape and applies pressure while the adhesives set.

08 Milling & Machining

The formed members are then machined to final dimensions using custom robots and traditional hand tools, and all penetrations and cuts are made.

09 Prefabrication

The lamellas are finished and treated. Then, we install any connection hardware before shipping.

Why Do AEC Professionals Prefer Glued-Laminated Timber?

Architects

Architects like our dowel-laminated timber for:

- Design flexibility

- Biophilic design

- Unique finishes and treatments

- Sustainability

Engineers

Engineers like our dowel-laminated timber for:

- Superior load-bearing capacity

- Long-lasting durability

- Resistance to warping, cracking, and splitting

Contractors

Contractors like our dowel-laminated timber for:

- Customizable sizes, shapes, and thicknesses

- Minimal waste and environmental impact

- Easy assembly of prefabricated components

Our Glued-Laminated Timber Services

Design Consultation

- Work with our experts to bring your vision to life

- Explore design possibilities and material options

Precision Manufacturing

- State-of-the-art equipment for precise cutting and assembly

- Quality control at every step of the process

Custom Finishing

- A variety of finishes to enhance the beauty and protection of your DLT

- Custom staining, painting, and sealing options

Get A Free Consultation From Tridome Structures

We value your privacy and will never spam you with unwanted emails. Your personal information is kept confidential and will not be shared with any third party.